News

COMPLETE DIGITALIZATION – THE TRANSFORMATION OF THE TILE INDUSTRY TOWARDS NET ZERO

As the global trend shifts towards sustainable development, the tile manufacturing industry is undergoing a profound transformation—where digital technology and green materials become essential drivers. The focus is no longer solely on design improvement and performance enhancement, but also on minimizing environmental impact—a bold move towards the Net Zero goal.

As one of the leading groups from Spain, Altadia—a strategic partner of Viglacera in Vietnam—is taking the lead in the green transformation of the tile industry. With a synergy of four renowned brands: Esmalglass-Itaca, Younexa, Fritta, and Vetriceramici, Altadia delivers comprehensive solutions that integrate advanced technologies and sustainability across every stage of production.

A soft-touch tile surface harmonized with green living spaces creates a sense of comfort and serenity in tune with nature.

Photo: Eurotile

A GATEWAY TO THE FUTURE

Design trends are becoming more diverse and better aligned with emerging surface technologies, aiming to optimize resources and explore advanced surface materials. Below are the major trends shaping the future of the tile industry:

NATURAL SPACES THAT NOURISH THE SOUL

Inspired by the Archinature and Soft Art trends, new surface technologies foster living spaces that blend with nature, offering calm and therapeutic environments. Tiles that mimic natural textures—with neutral tones and gentle veining—are not only aesthetically pleasing but also highly practical in contemporary architecture.

FULL DIGITALIZATION AND A COMMITMENT TO SUSTAINABLE TILE MANUFACTURING

Digital technology has revolutionized how tiles are designed and manufactured. The Digital Design Concept synchronizes design processes through 3D scanning technologies, not only reproducing 2D visuals but also recreating 3D surface structures (Digital Structure Surface).

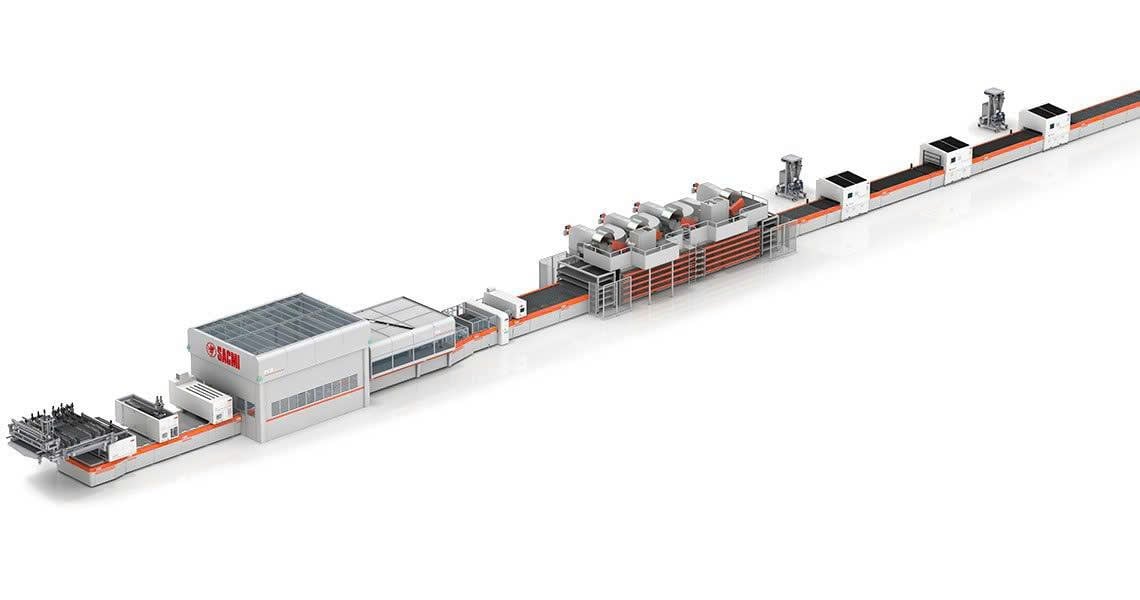

At Viglacera, state-of-the-art robotic systems apply up to 12 base color layers across different tile levels—from body to surface. Furthermore, the SACMI CONTINUA+ flat-pressing production line enables CO₂ emission reduction and operates with 100% automation. It can reproduce almost any sustainable material—such as wood, stone, and cement—under green manufacturing standards.

In addition, Esmalglass-Itaca has upgraded its DigitalGlass technology: water-based digital glazes and inks. This innovation significantly reduces water usage and emissions, contributing to environmental protection while still ensuring production efficiency and high product quality.

Together, Altadia, Esmalglass-Itaca, and Viglacera are reshaping the future of the tile industry with end-to-end digital technologies and optimized processes—enhancing product quality and opening up possibilities for unprecedented surface designs.

A SACMI CONTINUA+ automated production line at Viglacera and Eurotile ensures consistency, efficiency, and sustainability.

COLLABORATION FOR INNOVATION AND GLOBAL REACH

Success in digitization and green transformation relies heavily on strong partnerships. As a giant in the industry, Viglacera plays a pivotal role alongside Altadia in creating breakthrough values. Through this tight collaboration, Altadia has introduced cutting-edge technologies from Esmalglass-Itaca, Younexa, Fritta, and Vetriceramici to Viglacera—resulting in tiles with exquisite design, exceptional durability, and leading-edge sustainability. In the digital era, the tile industry is poised for a remarkable leap forward, powered by technology and eco-conscious materials.

Digital technologies enable the production of large-format tiles, elevating both elegance and spatial aesthetics.

Photo: Eurotile

Excerpt from the article “Complete Digitalization – The Transformation of the Tile Industry Towards Net Zero” by the Asia Pacific Design Director – Altadia, published in the Trend 26+ book.